Submitted by Tom Miles on

Spilling Engine Within Sawmill

Submitted by biolists on

Uniconfort Biomass Gasifier Installation

Submitted by Erin Rasmussen on

Spilling Steam Piston Engine

Submitted by biolists on

Uniconfort Vertically Integrated Direct Gasifier

Submitted by biolists on

Manufactured Gas In The House - historic document

Submitted by Jeff Davis on

Pederick Owner's Manual - Historic Document

Submitted by Jeff Davis on

Financing Biomass Gasification Technology in Rural Cambodia

Submitted by Tom Miles on

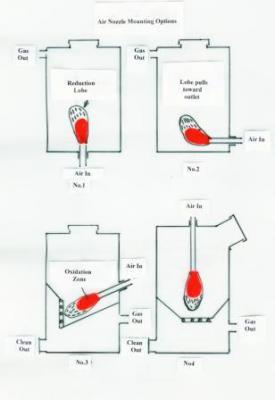

Open Core Reburn and Stratified Downdraft Gasifiers

Submitted by Tom Miles on

India: Aruna Biomass Gasification

Submitted by Tom Miles on

OSHA CO Factsheet

Submitted by Tom Miles on

The C-H-O Fuel Map

Submitted by Tom Miles on

India: Gasification of bamboo for electricity

Submitted by Tom Miles on

The Gasifier-Powered Cafe Racer: The Car of Yesteryear . . . Today!

Submitted by Tom Miles on

IEA Task 33 Technical Presentations from Spring 2007 Task Meeting

Submitted by Tom Miles on

Engine Tables Spreadsheet

Submitted by Erin Rasmussen on

Charcoal Gasifier No. 3

Submitted by Visitor (not verified) on

Charcoal Gasification No 5

Submitted by Visitor (not verified) on

Charcoal Gasifier No. 4: Operating the Charcoal Gasifier

Submitted by Visitor (not verified) on

Vidir Biomass Greenhouse Gas Displacement System

Submitted by Tom Miles on